Introduction of Intelligent Lighting Personnel Positioning System (I)

Intelligent Lighting Personnel Positioning System (hereinafter referred to as "the system") consists of two major parts, namely, intelligent lighting control and personnel precise location management. Through the integration of UWB precise positioning, IoT intelligent light control and other technologies, it solves the problems of optimising the energy consumption of lighting and the precise location management of operating personnel in coal washing/selecting plants.

1 System Overview

Intelligent lighting personnel positioning system (hereinafter referred to as the "system") consists of two major parts: intelligent lighting control and personnel precise location management. Through the integration of UWB precise positioning, IoT intelligent light control and other technologies, it solves the problems of optimising the energy consumption of lighting and precise location management of operators in coal washing/selecting plants.

Intelligent lighting control module can achieve "light on when people come, light off when people leave"; at the same time, it can also achieve lighting scene setting and remote monitoring, data collection and statistical analysis of energy consumption of lighting equipment, and alarm of lighting equipment. Personnel positioning module can achieve personnel location display, track playback, intelligent inspection, personnel management, and positioning alarm management and other functions. These functions can reduce the enterprise electrical energy consumption consumption at the same time, to improve personnel management efficiency and production safety norms provide the basis.

2 Intelligent lighting personnel positioning system general structure

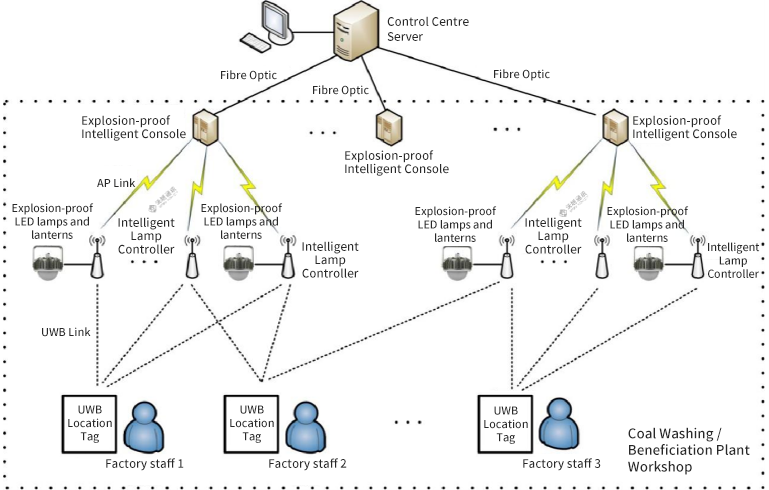

In the design of intelligent lighting personnel positioning system, Woxu Wireless and its partners jointly develop the positioning anchor combined with LED intelligent light control controller, so that it has both positioning and lighting control functions.

Intelligent lighting personnel positioning system hardware facilities include: control centre server, explosion-proof intelligent console (fiber optic transmission), LED lamps and lanterns, intelligent lamp control controller, Woxu Wireless personnel positioning tags and so on, the structure is shown below:

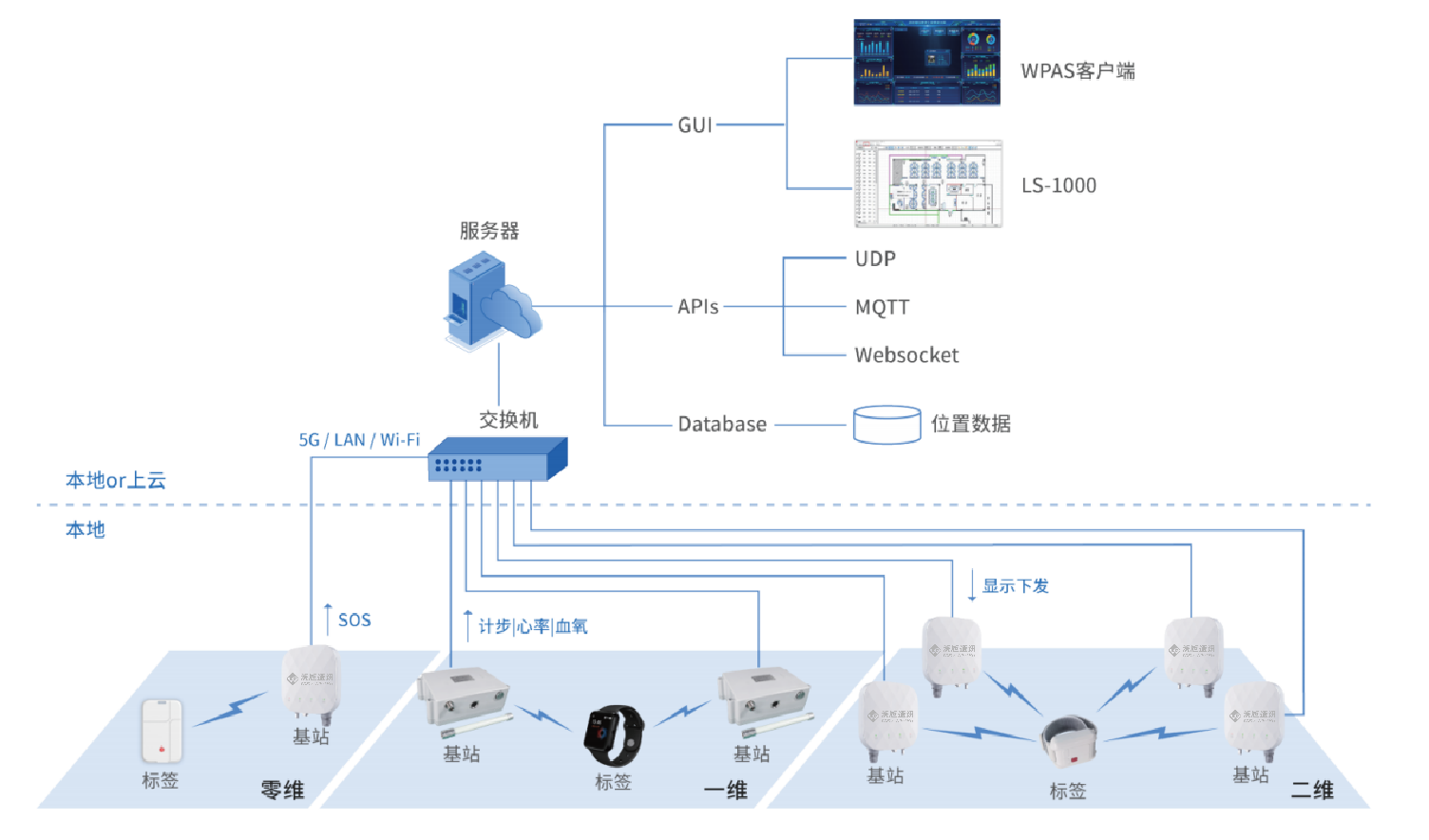

(1) Introduction of UWB wireless positioning system

UWB wireless positioning system adopts advanced UWB pulse wireless positioning technology, by installing positioning anchor in the production area and configuring UWB positioning tags for personnel entering the production site, it can realise real-time high-precision positioning for personnel entering the production site for operation/inspection, and the average accuracy of Woxu Wireless UWB wireless positioning system reaches 30cm in this complex application scenario.The wireless positioning system is based on the ultra-narrow pulse technology, by sending and receiving UWB pulse tags, the wireless positioning system can achieve high precision positioning for personnel entering the production site. The wireless positioning system is based on ultra-narrow pulse technology, which transmits data by sending and receiving extremely narrow pulses of nanosecond or sub-nanosecond. Using the advanced ultra-narrow pulse precise time-of-flight measurement technology, it realises precise ranging/timing at the bottom layer; combined with the position solving algorithm, it realises precise positioning at all layers. Electronic fence and SOS alarm developed based on the positioning function of Woxu Wireless UWB wireless positioning system are beneficial to the dynamic management of site operators to avoid unsafe events. The system has the advantages of high positioning accuracy, low power consumption, high security and strong anti-interference performance.

The whole architecture consists of hardware (anchor, tag), positioning engine software (C/S architecture), API interface. The tag and the anchor communicate through UWB pulse signals, the anchor collects the information data from the tag and forwards it to the positioning server, the data is processed by the algorithm of the positioning engine, and the precise location, electronic fence, alarm and other information is transmitted to the upper application or third-party platform through the open API interface.

(2) Introduction of Intelligent Lighting Management System

The system can implement unified opening and closing, single-lamp control, remote control, etc., to realise energy-saving lighting and real-time monitoring and management of lamps and lanterns, realise "people come to light up, people go out", ensure high efficiency and stability, all-weather operation, and control unnecessary lighting to effectively save power consumption.

Free grouping of lamps and lanterns in the factory area, realising full control, group control and single control of lamps and lanterns. Through the time-control plan task, each type of lamps and lanterns can be grouped in any way for timing control and dimming control; as well as whether the lamps and lanterns perform the mode of "light on when people come and light off when people leave", the sensing distance, the delay time and other parameters are set. According to the business scenarios of the coal processing plant, the general principle of the design is that in the areas where there are more personnel or important areas, such as the main washing workshop, screening workshop and train loading area, the mode can be set to always light up at night, and during the day, it can be switched off or set to the "people come to light up, people go out" mode; in the belt lane, the corridor, the pharmaceutical workshop, the pump room, the car loading area In the belt lane, long corridor, pharmaceutical workshop, pump room, car loading area and other areas where the frequency of personnel is not very high, it can be set as "people come to light up, people go to light out" mode; the raw coal warehouse, product warehouse area can be set as "people come to light up, people go to light out" mode during the daytime, and set as a mode of constant light at night. The raw coal warehouse and product warehouse area can be set as "light on when people come, light off when people leave" mode during daytime, and set as constant light mode at night. All the above areas can be flexibly adjusted and set according to the actual demand through the system platform.

3 Technical performance

(1) Realise real-time monitoring and control of personnel position in the plant, including main washing workshop, raw coal warehouse, product warehouse, screening workshop, trestle, concentration workshop, power distribution room, maintenance workshop, loading station and other major operation areas;

(2) Intelligent control functions of lamps and lanterns include real-time control, group control, single-lamp control, timing (time-controlled plan) control and dimming functions;

(3) Intelligent inspection faster, lamps and lanterns actively report voltage, current, power real-time collection statistics, real-time mastery of the state of the lamps and lanterns and power consumption statistics;

(4) support lamps and lanterns power real-time monitoring, lamps and lanterns failure the first time reported to the platform, and SMS or platform system pop-up notification of maintenance personnel, to avoid affecting the safety of production;

(5) Support "people come to light, people go lights out", the induction distance platform can be set, the trigger time is less than 1S;

(6) Positioning tags can be used for no less than 1 month on a single charge;

(7) extremely fast positioning response time, personnel position movement, the platform end response time is less than 3S;

(8) UWB precision positioning technology, positioning range can be set, positioning accuracy ≤ 0.3 metres;

(9) Support concurrent and full-duplex communication between intelligent light control controller and intelligent console, with stronger real-time and higher stability;

(10) The console supports optical fibre network to transmit data;

(11) Intelligent lighting and personnel positioning functions in the same software system to achieve, and can be opened to the outside interface;