Baosteel Hot Rolling Industrial Furnace Personnel Positioning Management

Project Background

The high temperature of hot rolling industrial furnace operation is prone to scalding, burning and burns; high temperature molten salt and molten metal will explode when they meet water; gas and controlled atmosphere are explosive gases, oil circuit, oil tank and oil reservoir are flammable and explosive facilities, if not used properly, explosions and poisoning accidents will occur.

Many repair operations are carried out in the furnace, the space is very crowded, natural lighting is not enough, ventilation conditions are very poor. Workers operating not only by the dust, sometimes also directly by high temperature, soot, toxic gases and corrosion of steel materials, the danger is great. Therefore, when operating and maintaining industrial furnaces, great attention should be paid to personnel safety. Baosteel Group proposes to install a personnel positioning management system in the hot rolling industrial furnace operation area as a way to improve production safety management and efficiency and reduce the probability of safety accidents.

Technical Solution

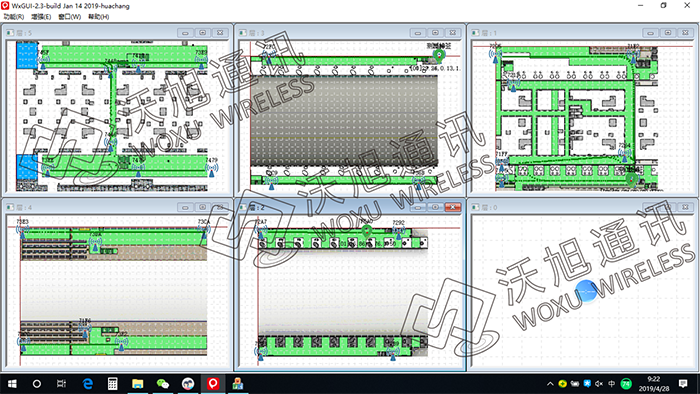

The personnel location management system adopts UWB ultra-wideband technology to locate the inspection personnel through the coverage of the hot rolling furnace to ensure the safety of personnel and avoid operation hazards.

Based on the personnel location data, it realizes the statistics of the number of personnel in the furnace, inspection trajectory, electronic fence alarm, video linkage, etc., to reflect the site situation and personnel status of the steel industry in an intuitive and timely manner, and improve the strength and efficiency of personnel safety protection.

Program realization

1) Real-time location display: the location coordinates of the inspection personnel are displayed on the map in real time, and for the edge of the device area (generally the road), no mis-positioning can occur, and no personnel outside the device can be mistakenly positioned inside the device.

2) Active alarm: personnel in danger can be actively alarmed by the SOS function button that comes with the tag label, and if the alarm is confirmed, the background can implement quick rescue according to the location of the personnel to ensure the safety of the personnel.

3) Personnel history track: you can view the activity track of the inspection personnel, and according to the name of the personnel, time period for track playback, to provide a decision basis for event processing.

4) Electronic fence: custom electronic fence, for part of the dangerous area, according to the personnel authority to determine whether access, detection of illegal entry system to give timely alarm; for the personnel with authority to detect the stationary personnel in the area, when the personnel have not been active for a long time system to give alarm information.

5) Analysis of the number of people in the region: the number of people in the furnace can be counted, and display the time of people in and out of the furnace.

6) Video linkage: Real-time location system and camera linkage fusion, real-time view of the factory site conditions and personnel distribution.

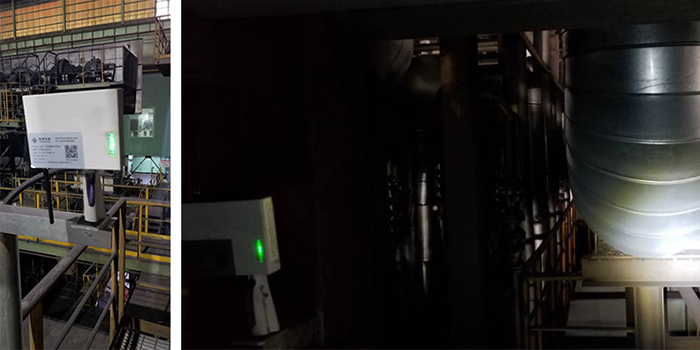

Anchor deployment and test effect

Site pictures