5G+ UWB Dual Network Integration Solution

——Adding "smart insurance" to Yonggang's digital workshop

Background and needs of the project

Jiangsu Yonggang Group Co., Ltd. is one of China's key production bases for construction steel and industrial materials. It has a complete production system of sintering, iron making, steel making, rolling and deep processing of products, with an annual steel making and rolling capacity of 8 million tons respectively. This time, Yonggang Lianfeng Steel's annual processing of 250,000 tonnes of iron-bearing zinc dust sludge comprehensive utilization project (referred to as the rotary bottom furnace project) covers an area of 42,000㎡ and has a huge management task.

*P1 the site of the Jiangsu yonggang

In the daily production and manufacturing process, the traditional management method of visualization is insufficient due to the numerous equipment in the converter workshop, the intricate and complex inspection routes and the frequent movement of personnel positions. This requires the use of the Internet of Things, cloud computing, big data technology, through the IoT equipment and supporting integrated system software, to achieve basic information management, intelligent access control management, positioning alarm management, intelligent identification, real-time alarm, emergency management, query analysis and other functions.

The interconnection of anchors and tags can reflect the dynamic situation of personnel in each area to the system in a timely and accurate manner, so that the management personnel can grasp the information and movement trajectory of production personnel on duty at any time for more reasonable scheduling management.

When an emergency occurs, the management center can quickly achieve the location of the personnel concerned based on the data and graphics provided by the system, and take corresponding rescue measures in time to improve the efficiency of emergency rescue work.

*P2 Deployment and application of the anchor

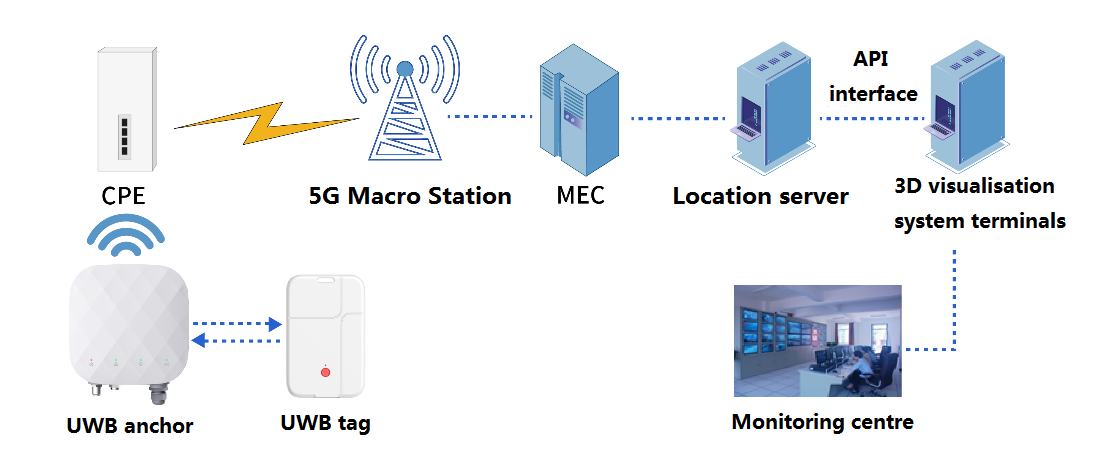

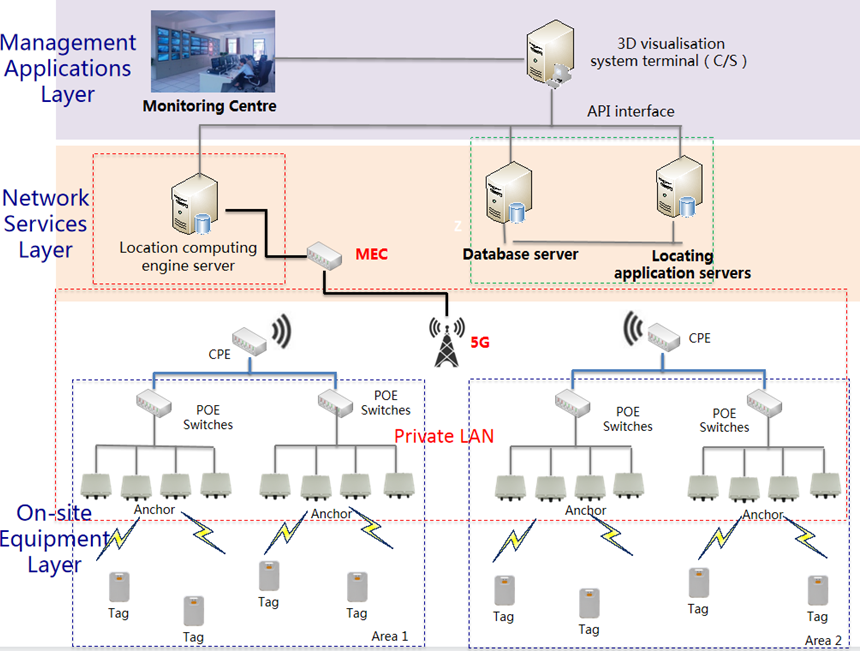

5G+UWB Smart Factory Solution

Jiangsu Yonggang's converter project is huge. Woxu combines the latest IoT UWB positioning technology and 5G communication technology, using 5G network as the transmission medium for UWB positioning technology, deploying eight 5G macro stations, sixteen 5G CPEs and a set of MEC private deployment within the plant to achieve full coverage of the 5G network within the plant.

*P3 Application architecture

A total of 335 UWB positioning anchor were deployed in the raw material pre-treatment workshop, raw material workshop, direct reduction workshop of rotary bottom furnace, waste heat boiler workshop and finished product workshop, with each worker wearing a personnel positioning tag. The multi-dimensional positioning mode of 0-dimensional presence detection, 1-dimensional linear trajectory positioning and 2-dimensional regional plane positioning is adopted to realize real-time monitoring of personnel movement within the plant, enabling visualization and control of personnel locations within the plant.

* P4 5G+UWB Architecture diagram

- Intelligent personnel management Managers can view the real-time location, historical trajectory, access control data and basic information of relevant personnel in real time according to actual needs, and realize the overall control of personnel in the plant through a graphical display interface.

- Precise management of key areas Intelligent supervision of personnel presence, overcrowding, absence, presence information, presence data analysis, etc. in key areas can be linked to the production management system to link monitoring and control and intelligent alarm reminding of key areas, realizing precise supervision and management of heavy risk areas.

- Safety warning and control Through the functions of area overcrowding, restricted area, detention alarm, electronic fence, access control, inspection management, one key alarm and call for help, data analysis, etc., to achieve intelligent control of the plant, significantly improve the safety and management efficiency of the plant, reduce the production safety hazards in the plant, and reduce the risk of personnel in the production process.

- Intelligent inspection and control According to the reserved equipment point inspection system interface, receiving point inspection system planning path, the real-time location of the point inspection personnel and inspection tasks through the platform way to show and share, management can real-time view the completion of each inspection task. The information corresponding to inspection records and time and space can be automatically entered into the management system, while supporting abnormal alarms in the process of point inspection.

- Multi-system integration Through the intelligent function and the precise interconnection and control of the second gate access system, video monitoring system and production management system, the real-time data of the personnel and vehicles in the factory area can be controlled by big data intelligent analysis, thus realizing the purpose of intelligent, data-based and information-based control of the factory area.

- The value we offer to our customers The introduction of the 5G+ UWB dual network integrated management solution has ensured the security of network transmission and effectively reduced network latency and costs for Jiangsu Yonggang Group.

At the same time, the high-precision personnel positioning management system provides comprehensive and fine visualization management for the construction of the digital workshop of the converter, graphic display, control of key areas, data interchange and interaction, etc. to provide visualization data services for the daily production, scheduling, control and safety operation of the converter, truly realizing the intelligent, data-oriented and informative plant, creating a model of intelligent manufacturing in the steel industry and leading the intelligent transformation of steel.