Overseas Case Study|UWB Location Services in a US Steel Plant

Project background

Safety production is a must to ensure the sustainable and healthy operation of steel plants. With the trend of intelligent manufacturing, a steel plant in the US has introduced Woxu's UWB location system to establish an intelligent safety management platform and empower safety production with a digital intelligent factory.

With years of experience in the industry, Woxu's technical staff keenly found out that behind the steel plant's positioning demand was its urgent need for intelligent management innovation of safety production.

After a detailed evaluation and research, Woxu found that the steel plant had long and complicated production processes, including coking-sintering-iron-making-steel-making-hot rolling and other serial processes, which made it difficult to clarify the scope of safety responsibilities in safety management, difficult to track hidden dangers on site, difficult to quantify safety management, difficult to analyze, difficult to count, inaccurate, long cycle time, risk visualization and full participation in safety management, and safety The analysis ability needs to be strengthened. Therefore, the steel plant needs to strengthen the integrated real-time control function in the safety management system, and also needs a more linked and intelligent system to assist in the safety alarm and control capability.

Woxu responded quickly and actively to the cross-country and cross-time-zone communication and collaboration, and provided efficient, flexible and mature solutions. The project was delivered successfully with full support in the implementation.

Technical solution

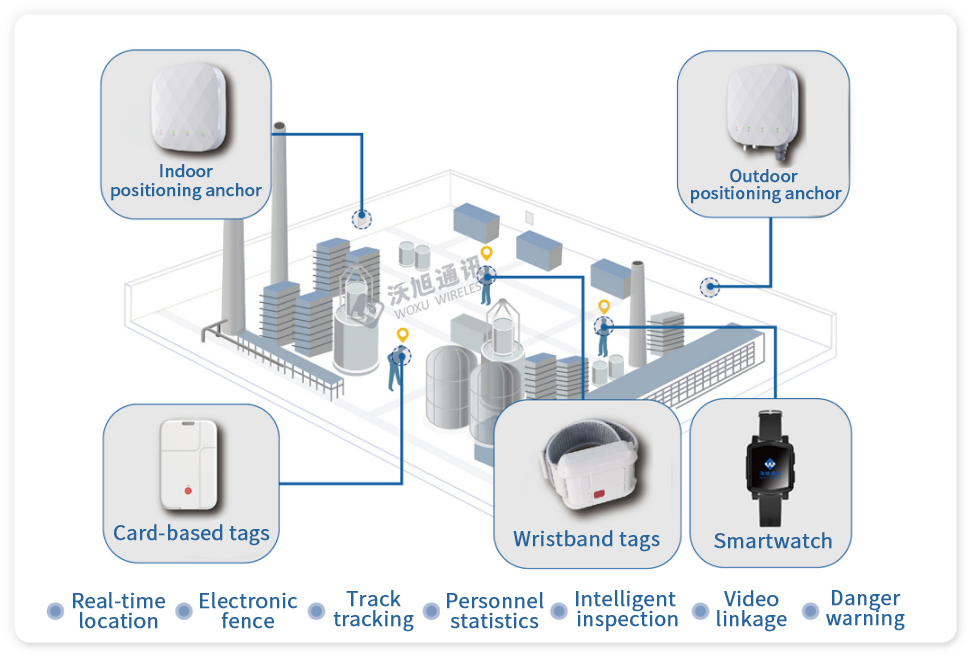

The steel plant personnel location management system uses UWB ultra-wideband technology to achieve the positioning of workshop inspection personnel through the coverage of the workshop, to ensure the safety of personnel and avoid hidden operational hazards. Based on the personnel location data, it realises headcount statistics, inspection trajectories, electronic fence alarms, access control swipe cards, etc., reflecting the site situation and personnel status in an intuitive and timely manner, improving the strength and efficiency of personnel safety protection.

Programme realisation

1) Real-time location.

Real-time display of the location coordinates of the

inspection personnel, for the edge of the device area, can not

appear mis-positioning, can not be mis-positioned outside the

device personnel to the device.

2) Active alarm.

Personnel in danger can be actively alarmed by the SOS

function button that comes with the tag label, if the alarm is

confirmed, the background can implement quick rescue according

to the location of the personnel to ensure the safety of the

personnel.

3) Historical track.

You can view the activity track of the inspection personnel,

and can play back the track according to the personnel's name

and time period to provide a decision basis for event

processing.

4) Electronic fence.

Custom electronic fence, for part of the dangerous area,

according to the personnel authority to determine whether to

access, detection of illegal entry system to give timely

alarm; for the personnel with authority to carry out regional

personnel stationary detection, when the personnel have not

been active for a long time system to give alarm information.

5) Access control system.

Based on the characteristics of the system's high-precision

positioning, positioning equipment can be added at the

entrance position of the ironmaking to achieve the auxiliary

function of time and attendance, recording the access of

personnel and recording the time.

6) Video linkage.

When a specific electronic fence triggers an alarm event, the

camera bound to that electronic fence automatically captures a

photo image, and the SOS alarm is based on the camera of the

electronic fence, which can be viewed in the alarm record.

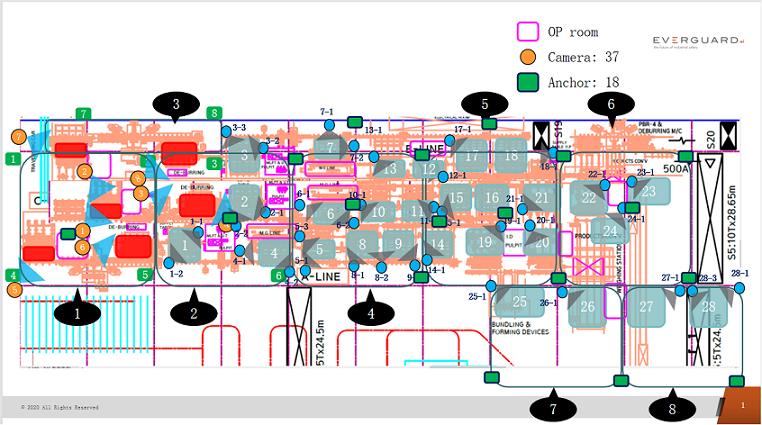

Anchor deployment and test results

Site Photos

Value Summary

Through the UWB high-precision positioning system, the whole process control of outsourcing personnel, visitors and operators can realize real-time information, process control, operation standardization and effective control of safety risks in the intrinsic safety management of the steel plant.

The introduction of UWB high-precision positioning technology in the U.S. steel plant is one of the many overseas businesses carried out by Woxu. While promoting the agile transformation of traditional manufacturing industry, Woxu's continuous breakthroughs in business, process and technology will continue to lead the new direction of industry application development and solidify the core competitiveness.