Personnel Location System in One Of Unilever's Factories

Background of the Project

One of Unilever's factories has a large number of staff, which makes it difficult to manage staff and can easily lead to management loopholes, which in turn can lead to unnecessary management problems. In addition, there are many flammable and explosive areas in some of the raw materials and production areas, which can easily lead to fire and irreparable damage. This, coupled with the large scale of the factory, makes it impossible to hold people accountable for problems that occur due to lax management, making it possible for the perpetrators to take a chance and let slip a little, which could lead to more serious problems. In the long run, it will be difficult to improve the factory system, and the safety of the factory personnel and goods safety can not be guaranteed.

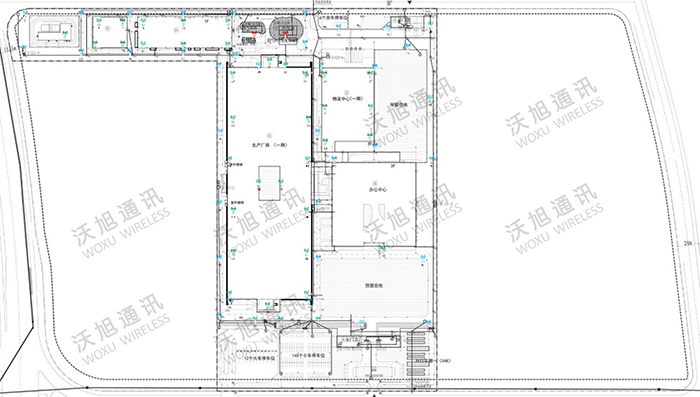

*P1 The site of a Unilever factory

With the installation of a personnel location system in the factory, employees can be evacuated immediately in the event of an accident, while the system provides real-time statistics on the number of personnel at the assembly point to ensure safe evacuation. If there are missing employees, the system can also be used to locate the employees and organize rescue in the first instance, so as to ensure the personal safety of the employees in multiple ways and avoid greater losses!

Breakdown of project requirements

The workshop covers an area of over 20,000 ㎡and employs over

300 people, including office staff, workshop operators and

management staff.

Requirements:

1. Real-time personnel location information query, historical

track query, accuracy within 1m.

2. The number of personnel can be counted with 100%

accuracy.

3. When people are in danger, alarm information can be sent to

the management platform in time.

Programme description

The system architecture consists of three parts: positioning

base station, tag and positioning engine server.

Workflow:

tag emits UWB signal → base station receives UWB signal →

master station gathers UWB data and forwards it → computing

server carries out data settlement.

*P2 UWB positioning system architecture

Anchor deployment

1. In open area with a radius of 30m one anchor for

grid-shaped deployment, such as a larger conference room or

office, etc., just install it around near the wall to form a

rectangle to cover the whole office area.

2. In the corridor area, one anchor is deployed along the

corridor with a radius of 15~30m.

3. Install one anchor in the centre of the stairwell and small

rooms.

4. The anchor is far away from air conditioning vents,

fluorescent lights and other obvious obstructions, so that

people can see the anchor from any angle in the area to be

covered.

*P3 Layout of anchor

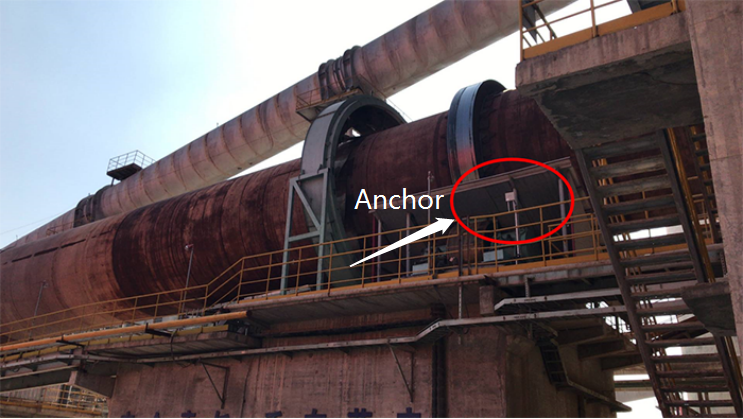

*P4 Aapplication of anchor

Customer value

The high precision personnel location management system provides Unilever factories with real-time personnel location information query, historical track query and real-time statistics on the number of personnel at the assembly point. It provides comprehensive and fine visual management for factory digital construction, graphic display, key area control and data interaction, and provides visual data services for daily production, scheduling, control and safe operation of the factory.It provides a practical guarantee for ensuring the personal safety of factory personnel and personnel management, and truly realize the data-based, information-based and intelligent management of the factory.