"UWB + e-paper" creates a new path to paperless intelligence

In the face of the digital wave and rapidly changing market demands, traditional production and management methods can no longer meet the rhythm of modern production and life. For example, electronic equipment manufacturing plants generally prohibit communication equipment, and traditional broadcasting methods are difficult to find people. Secondly, a large number of material trolleys are used in production workshops, which are prone to disorderly parking, scheduling difficulties and difficulties in locating them, resulting in lower production efficiency.

At the same time, the "carbon neutral" and "carbon peak" < Double Carbon Goal> has pointed out the direction of technology development for the sustainable development of enterprises, and the transformation of paperless intelligent factories is imminent. Facing the trend and challenges, Woxu Wireless, as a smart factory solution provider, also integrates its location data services with various cutting-edge technologies and is committed to creating a new economic ecology.

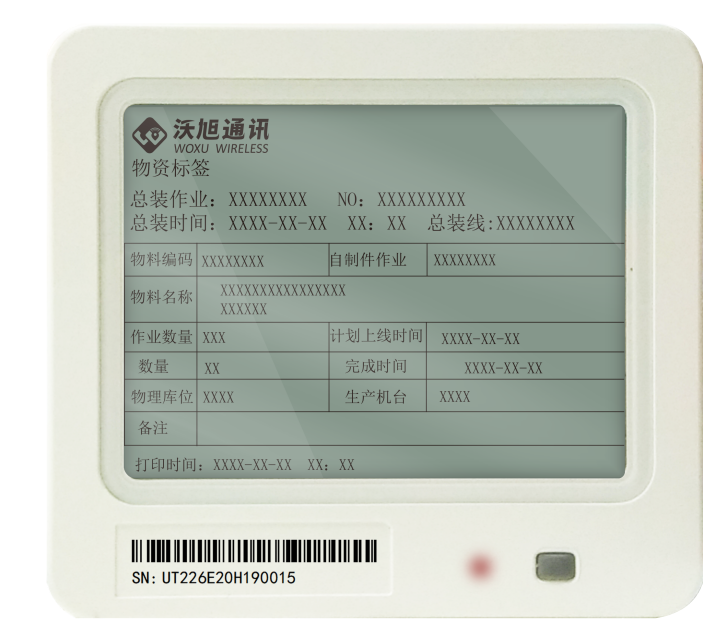

The UT-226-E4 ink screen tag is a displayable material tag developed by Woxu based on UWB technology and market demand, supporting both ToF and TDoA positioning methods. The product is equipped with a 4.2" electronic ink screen, which supports the display of material information, time and power, etc. The multi-page display supports key flipping. The product is powered by high-capacity disposable batteries and has a typical operating time of more than 3 years. The main applications are in the fields of Industry 4.0 and warehousing and logistics.

Key features

Low power consumption - The e-ink screen only consumes power when turning pages etc. If the display is not refreshed, the image on the display remains even if the power is switched off, making it very energy efficient.

High resolution ink screen - Material information, time and power display

Display down - Platform down display, multiple pages support key flipping

"UWB + e-paper" for paperless intelligent production and management

1. Production process flow Replacing the traditional manual process flow card, the ink screen label is used as the unique identification and generates a unified format work order, realising paperless information transfer and production process traceability, with all information being data-driven, avoiding writing errors and reducing costs and increasing efficiency for enterprises.

2. Intelligent material scheduling Ink screen labels are installed on transport vehicles transporting materials to replace paper labels, realising visual informationisation of material management and facilitating tracking and control of materials. According to the electronic ink screen label display information quickly and accurately verify the accuracy of the transport truck materials, wirelessly update information, improve efficiency and reduce human error.

3. Warehouse visual management (1) Wireless update of goods inventory, reducing manual alteration action, improving correctness and personnel efficiency. (2) Visual management, materials at a glance. preservation, traceability more simple. (3) Reuse to meet environmental requirements. (4) Simple and quick deletion of individual label information at the end of use, eliminating the tedious process of disposal and the risk of information leakage.

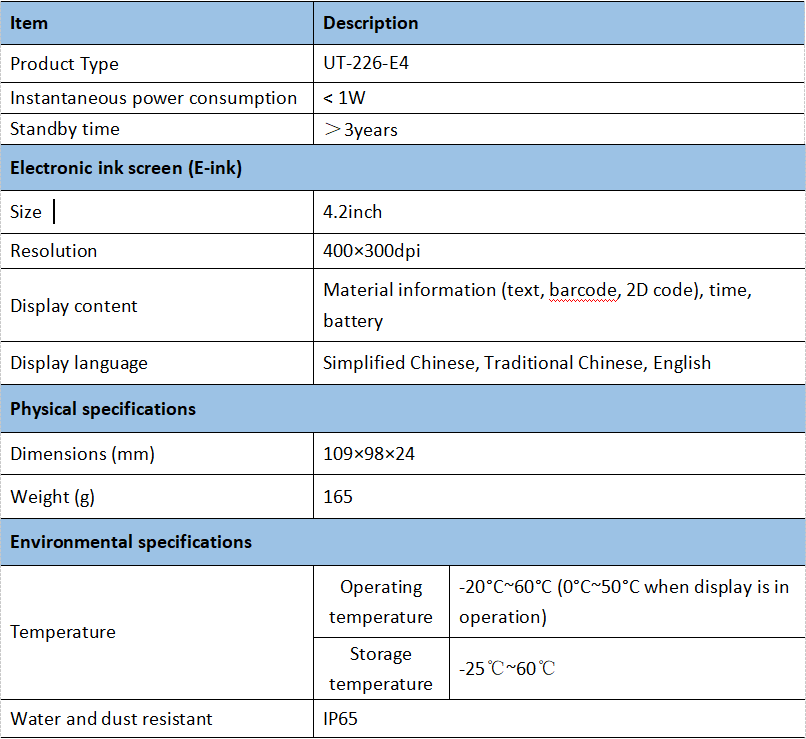

Product specifications