UWB High Precision Location Services ——to improve the efficiency of a listed group's personnel

production management

Background and needs of the project

Group C is a widely influential micro-motor product development, design and manufacturing listed company, with a factory covering an area of over 140,000 square meters and an annual motor shipment of over 200 million units. However, due to the large number of people on the production floor, it is not easy to quickly assess the presence of production line staff, which makes it easy to manage situations such as staff straggling off duty.

In order to better promote the intelligent construction and realize the fine and intelligent management of the factory, Group C started an intelligent transformation project this year. With the help of Woxu's UWB high-precision indoor positioning technology, the project is able to obtain the working hours invested by each employee in the manufacturing process through high-precision positioning of the production line staff, which can later be used to analyse the production capacity according to the production reports, thus optimising the production structure and improving production efficiency.

Project Description

Industry: Manufacturing

Project cycle: 2 months to complete deployment

Main business applications: location distribution and trajectory tracking, 3D effect presentation,

working hours statistics, one-card, and sharing of working hours statistics with MES and other

systems.

11,000 square meters of workshops fully covered, 6 floors of workshops, Positioning of more than 2,000

employees

Core pain points

1. Traditional manual verification, time-consuming and laborious

Group C had previously been using traditional manual supervision methods, which could not effectively

monitor and count on-the-job data and was very inefficient.

2. Data silos, difficult to manage

Data is scattered, production data is not connected and interactive, and it is difficult for management

to make reasonable analysis and optimisation of capacity efficiency.

*P1 Traditional manual verification

UWB Smart Factory Solution

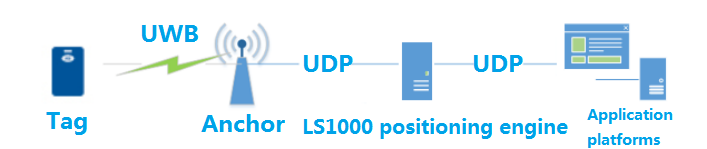

The Group C personnel location management system is divided into 4 layers, the location tag (terminal), the location anchor, the calculation engine and the WPAS management platform. The positioning tags and the positioning anchor communicate via UWB pulse signals. The positioning anchor transmits the received positioning tag data via wired Ethernet to the LS1000 positioning engine for data analysis and processing, and transmits the processed precise location to the upper layer application via an open API interface.

*P2 personnel location management system

A total of 58 UA-210 indoor anchors are deployed in a 6-storey workshop of about 11,000 square meters, positioning around 2,000 people. All employees wear card-type positioning tags and adopt a two-dimensional regional plane positioning mode to realise business applications such as personnel location distribution, trajectory viewing, working hours statistics and three-dimensional presentation, and dovetail with the MES system and personnel management system to share working hours statistics, effectively improving the efficiency of production line personnel management.

*P3 MES system

-

1. Real-time positioning management:

Realizing dynamic management of production line workers, you can view the real-time location, distribution area and activity trajectory of the personnel being positioned, so as to grasp the personnel's dynamics at any time and anywhere, with an average positioning accuracy of 30cm. -

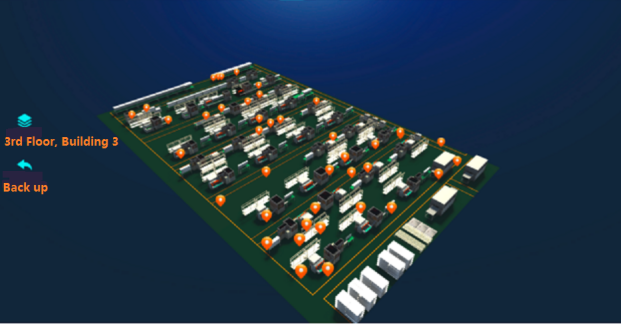

2. 3D visualisation:

Using 3D visualisation technology, the location information of production line workers is presented in 3D scenes in real time, so that the location distribution of production line workers in each layer can be displayed more intuitively and visual management can be achieved.

*P4 Personnel Management Platform

-

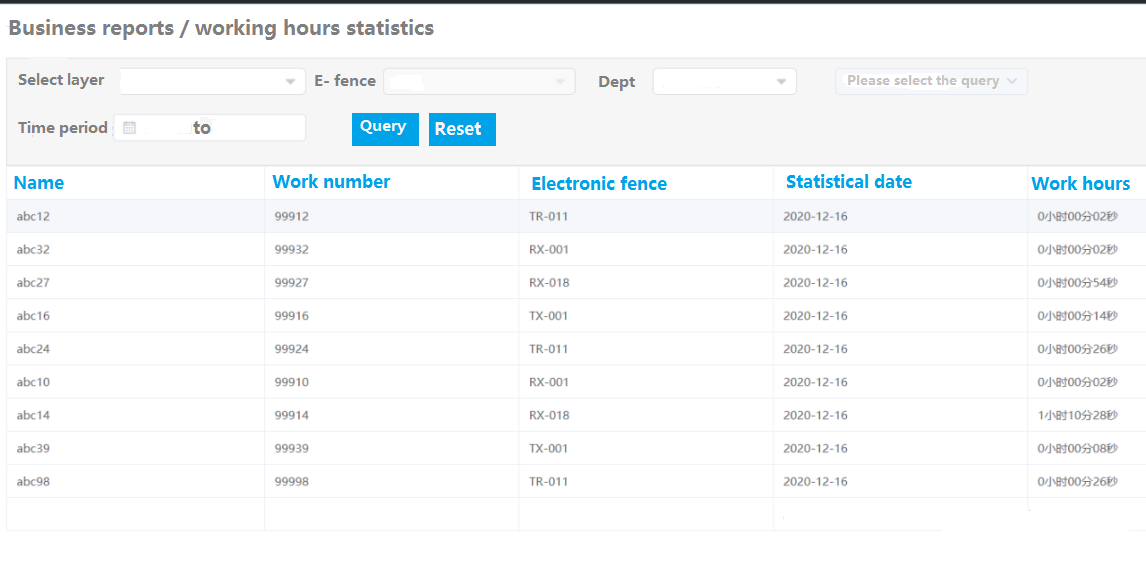

3.Man-hour statistics:

Customised electronic fences provide man-hours statistics for targets within the fence, and with intelligent algorithmic filtering, can achieve flexible time away from work configurations to meet the man-hours statistics needs of different industrial scenarios.The MES system can obtain the personnel working hours in real time through the interface and correlate with the task work order, so that the labour cost of the work order and the timeliness of the task completion can be automatically calculated.

-

4. One card function:

By integrating RFID into the positioning cards worn by personnel, the system can support business needs such as access control and consumer payment while realizing positioning.

Customer Value

Intelligent reform has always been a difficult and key point for traditional factories.

The application of information technology is the key to victory in this innovative reform path of Group C, which has achieved efficient management of production personnel efficiency. A set of 3D personnel management platforms based on UWB positioning technology has been established to achieve visual management, which is then successfully linked with systems such as MES to release the real value behind the data. This allows the group's management to quickly check the presence of staff, and monthly statistics of working hours can be directly based on the platform data for reference audit of attendance. In addition, through the comparison of working hours and output, capacity efficiency can be optimised, human resources can be allocated and utilized more rationally, and decision-making can be accelerated, helping to build a digital lean factory.

In summary, Group C has successfully achieved the transition from traditional management to intelligent production management with the help of the UWB smart factory solution, promoting the deep integration of a new generation of intelligent information technology with the manufacturing industry. As a typical manufacturing enterprise, its information technology practice is worthy of reference.

Note: Due to confidentiality, the name of the company has been omitted from this article, if you want to know more about the solution after reading, please contact Woxu Wirelss.