UWB positioning technology to promote the carbon fiber factory "wisdom to change the number of turn" to go deep to the real

Industry Background

As a national strategic new material, carbon fiber is widely used in modern industrial system with its excellent comprehensive performance. In recent years, with the support of relevant national policies, the domestic carbon fiber industry has been making breakthroughs in key technologies, expanding its production capacity and improving its market competitiveness.

Behind its strong momentum, the production efficiency and safety guarantee of carbon fiber manufacturing plants are particularly important. Therefore, major enterprises have stepped towards the road of intelligent reform and digital transformation, driven by digital technology innovation, promoting the integration and development of new generation information technology and advanced manufacturing, and comprehensively improving the intelligence level of enterprises in various aspects such as design, production, management and service.

Case Introduction

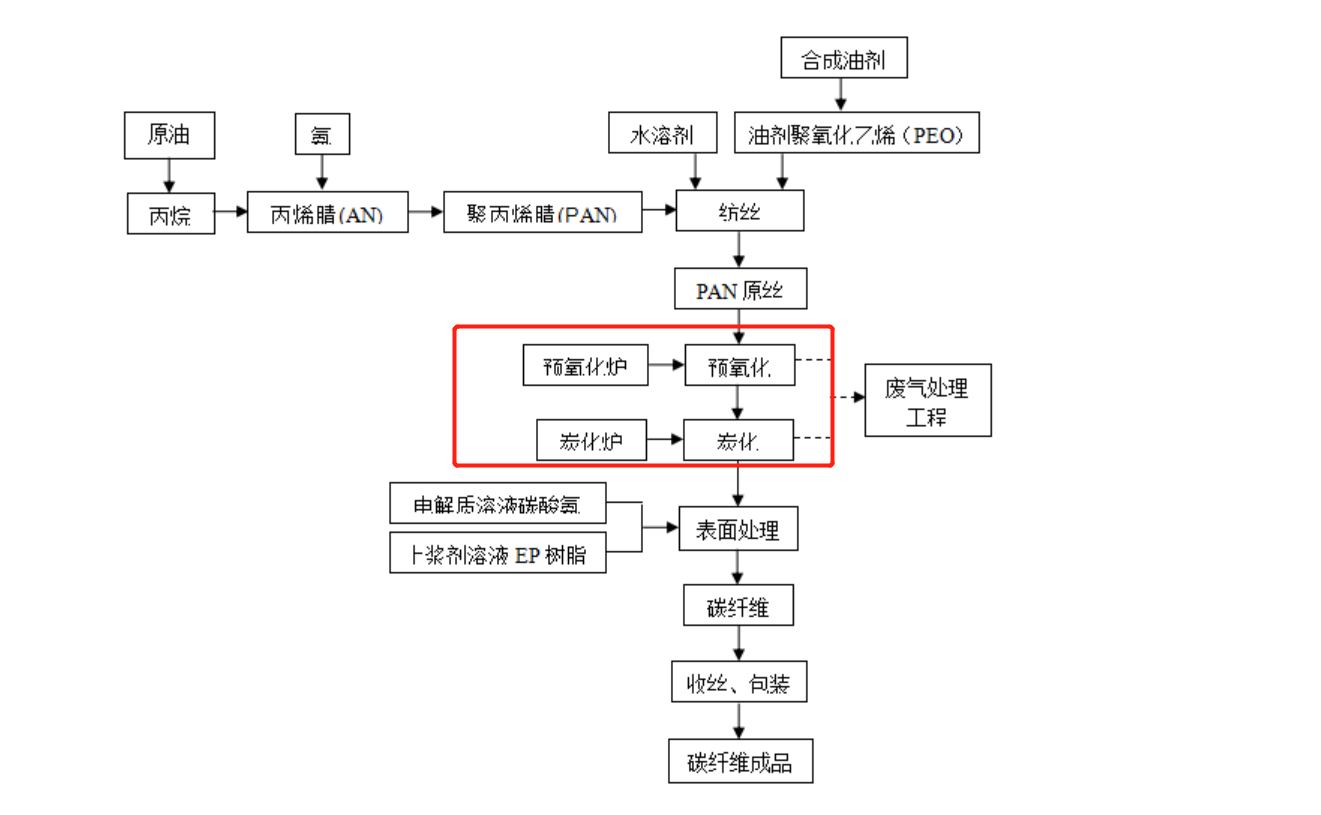

The carbon fiber production and manufacturing process contains a series of complicated processes, among which the pre-oxidation process is a key step in carbon fiber production, which involves a variety of high-temperature devices such as oxidation furnaces and carbonization furnaces, and under normal circumstances only designated shifts can work in them. In order to better reduce the operation risk in the high-temperature device area and improve the personnel control ability, a carbon fiber group in Jiangsu Province used Woxu Wireless UWB factory positioning system in the digital transformation of the factory to realize the precise division and control of the area and efficiently solve the safety problems of production management.

Application Description

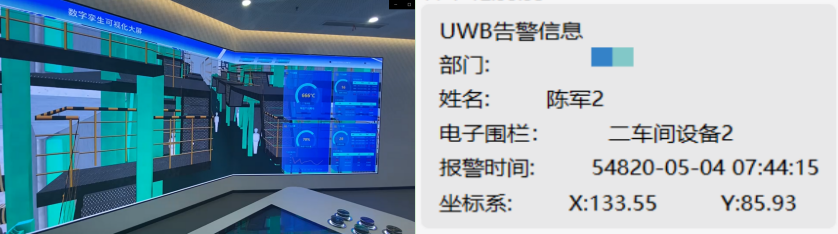

By deploying UWB positioning base stations in the high-temperature device area, personnel wear UWB positioning bracelets to accurately obtain the location data of the plant operators and integrate the collected location data with the digital twin platform for three-dimensional visualization and intuitive display, breaking data silos and efficiently solving the safety problems of production management.

By setting flexible electronic fences for perimeter alarm management in the high-temperature furnace area, the unsafe behaviors of personnel such as non-authorized entry, overstaffing and overtime are circumvented to ensure the implementation of behavioral norms, and the alarm records generated by the platform are pushed to the enterprise WeChat synchronously to eliminate the hidden danger of accidents.

Final Summary

A carbon fiber factory in Jiangsu, as a local private enterprise, has achieved accelerated catch-up in the new material industry track, and is committed to building the largest carbon fiber composite material production base in China. The digital transformation and upgrade has realized the integration and linkage of UWB, monitoring and digital twin platform, which provides the guarantee for the enterprise to realize the double improvement of safety management and efficiency management. At the same time, it also promotes the wisdom of the carbon fiber factory to change the digital twin to go deeper and more practical. To further enhance the international competitiveness of domestic carbon fiber add brick and mortar, and inject new green dynamic energy for high-quality development.