How to achieve transparent and intelligent management of wire-side logistics?Case Study|Creating intelligent and transparent management of the entire process of lineside logistics

The logistics system, especially the lineside logistics, like the veins of the human body, carries the basic material supply for the daily operation and maintenance of each factory, and also runs through the whole production process. In some typical discrete industries such as electronics manufacturing, automobile manufacturing, home appliance manufacturing, etc., enterprises need a wide range of materials for daily production, and the production output is high and fast-paced. In order to ensure the uninterrupted output of the production line, it is necessary to accurately control and judge the types, properties and status of all materials and semi-finished and finished products, in order to maximize the guaranteed output by timely adjustment of production and material plans accordingly. At the same time, this information can also push back the adjustment of procurement plan, avoid the accumulation of raw materials and semi-finished products, and optimize the storage and production line space. Therefore, the digital management of lineside logistics came into being.

Take a 500 strong daily necessities group production workshop as an example, the material operation in the factory used the traditional mode a few days ago, i.e., through the manual under send the bill of goods demand, the warehouse to receive for batching, through a number of areas flow to the production line. In the traditional mode, there is a time gap between the information flow of production, planning and warehouse departments, and the materials lack the management of the intermediate flow process, and paper documents are used to print the material information and quantity, which wastes consumables and manpower. Under the trend of smart manufacturing development, the group integrated and docked the existing SAP and RTCIS systems with Woxu's UWB precise positioning system to build a business platform with centralized processing of big data, which solved the pain points of the above-mentioned traditional model and achieved transparent, intelligent and paperless logistics management with efficient collaboration among production, planning and warehouse. In-plant material operation tracking throughout the whole process, helping to upgrade the line logistics digitalization.

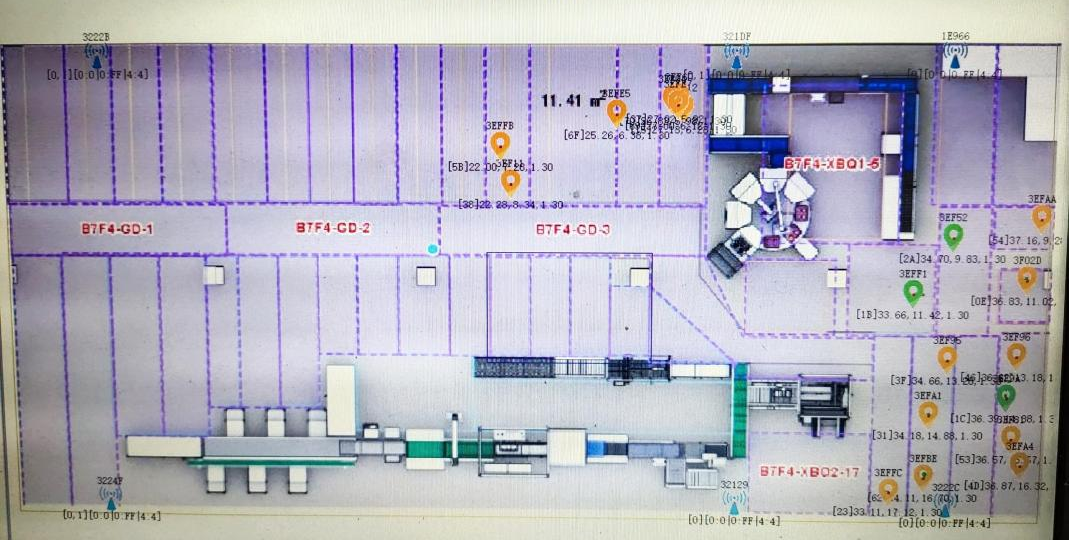

By deploying UWB positioning base station in the corresponding area and binding the UWB ink screen positioning tag to the shovel plate, the core algorithm can realize the location information, flow tracking and automatic allocation of storage position of the materials on the shovel plate in the factory warehouse, workshop suspension area, workshop line side warehouse, production supply line and other areas. At the same time, combined with the field configuration of the large screen signage and staff handheld tablet to achieve real-time visual management, reduce labor costs, improve the lineside logistics flexibility and digital management.

Lean management of wire-side warehouse to reduce production waiting time

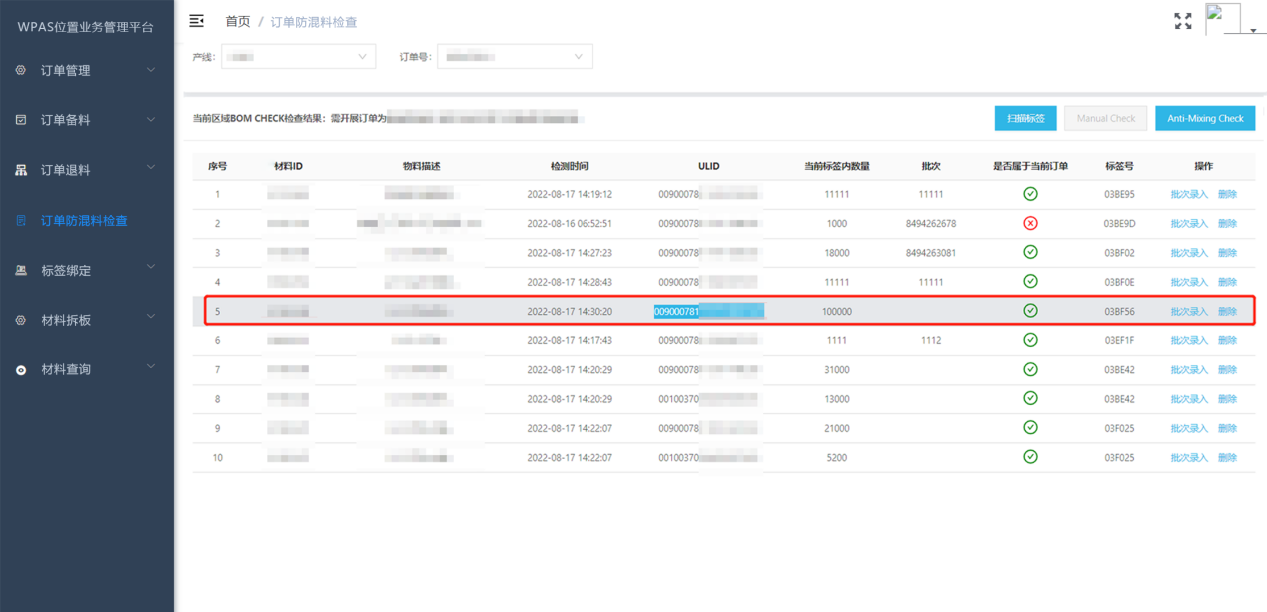

Waiting waste is one of the eight wastes of lean management, through Woxu UWB positioning system to obtain material information and quantity, compare the quantity in the order demand, determine whether to meet the production needs, and automatically notify the relevant person in charge of material preparation by email when the spare quantity is insufficient, reduce the waiting time for order switching, efficiently and accurately realize the overall planning of materials and production sequencing, greatly reduce the production stagnation caused by insufficient materials and production scheduling. It can greatly reduce the stagnation of production caused by material shortage and production scheduling, and greatly reduce the production waiting waste caused by material shortage for enterprises.

At the same time, warehouse material preparers can also quickly lock the material storage position that needs to be prepared through the positioning system, reducing the time to find materials. The system can also flexibly adjust the number of days of material preparation according to the leave situation of the relevant post staff to avoid accidental losses caused by work negligence.

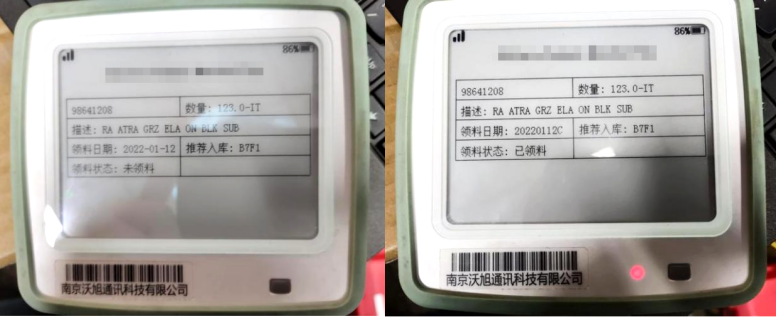

Electronic paper replaces paper labels to realize paperless workshop

UWB positioning labels with ink screen are used to replace the original paper labels, which can flexibly display material status, batch number, quantity, date and other information. The ink screen can also combine with the actual production situation to dynamically update the information related to semi-finished products, returned workpieces, SAP unstocked, surplus material inventory and returned material off list in a timely manner, reducing the manual printing of labels, labeling, label modification actions and realizing paperless management.

For the reform of a top 500 daily necessities group, Woxu used UWB positioning technology based on the concept of intelligent and modern factory management to provide a reliable solution for the digital management of lineside logistics, transforming the traditional mode of manual work in production logistics into an efficient, convenient and intelligent digital lineside logistics mode, and efficiently improving the efficiency of material flow and workshop production. It also lays a solid foundation for the group's continuous improvement on the road of digital lean management.